Machining

We specialize in precision machining of high-quality parts and products in non-corrosive materials.

Our workshop is equipped with 15 CNC machines from well-known and trusted brands, ensuring reliable and consistent performance.

Our machines can handle dimensions from approximately Ø50 mm up to Ø1740 mm, allowing us to support both small and large-scale production with high precision.

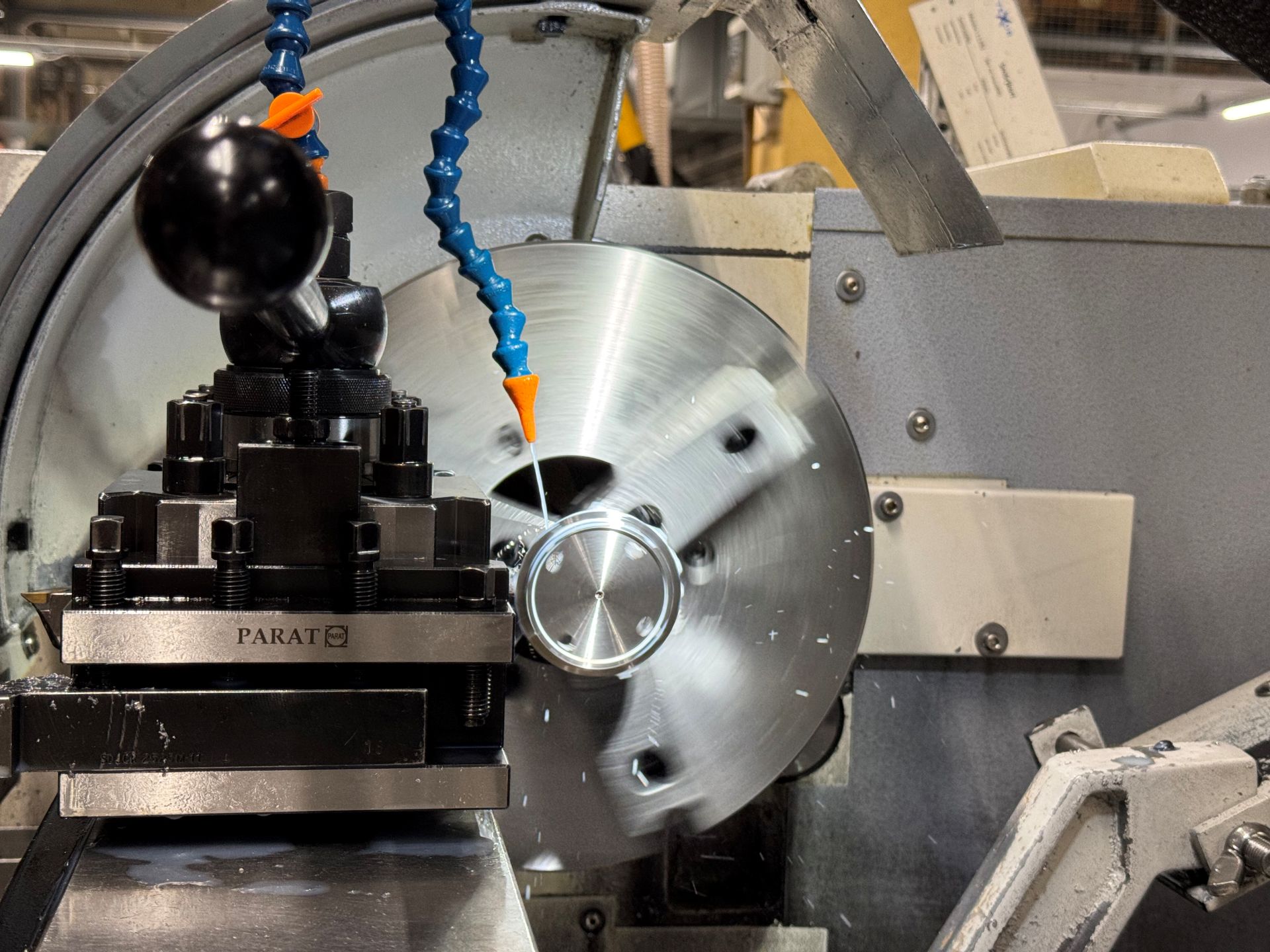

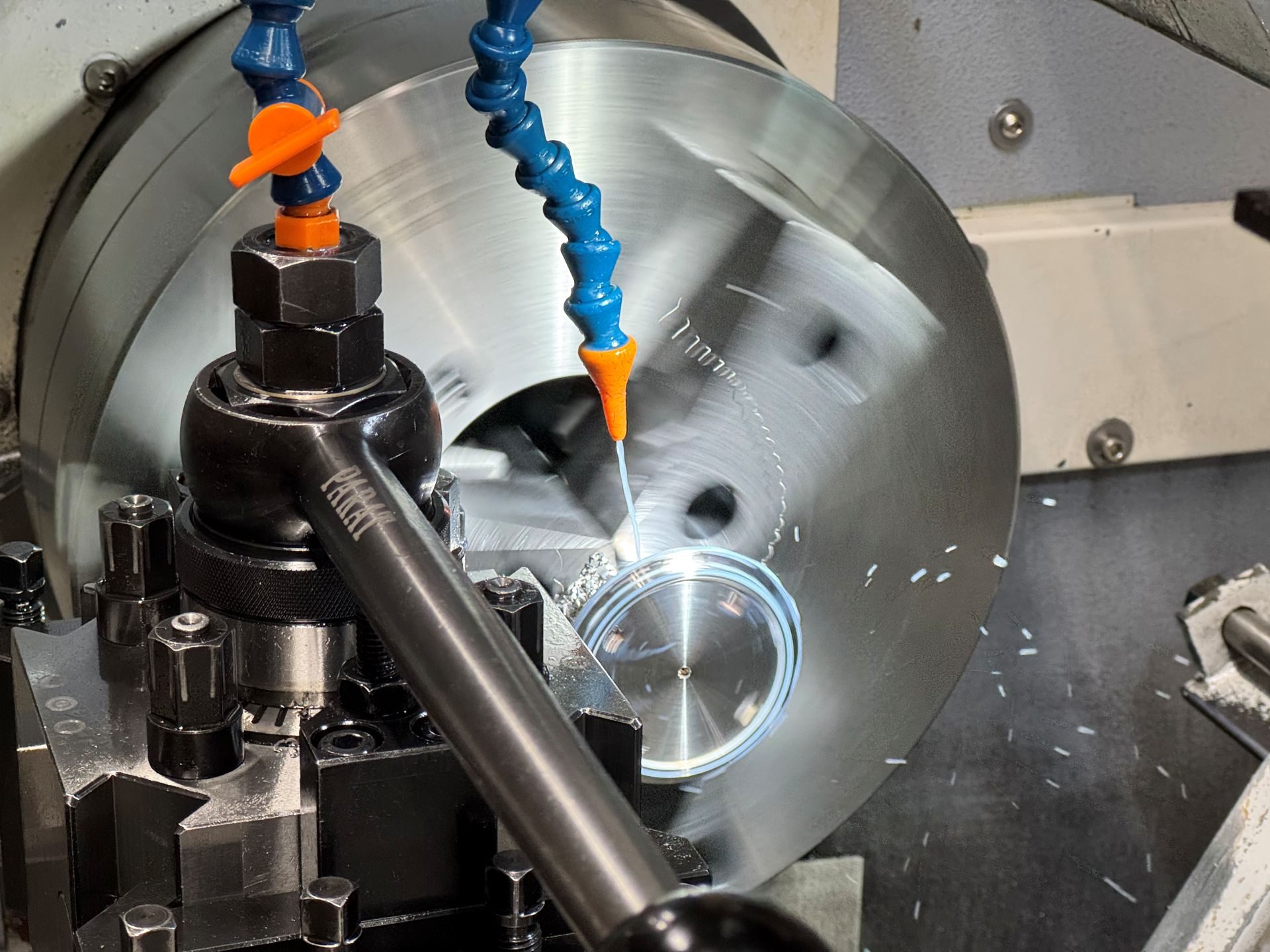

VTL - CNC Vertical Turning Lathe

We operate five CNC Vertical Turning Lathes in various sizes, equipped with X, Z, and C axes, enabling high-precision machining of complex, heavy-duty parts.

These machines are designed for parts with large diameters and demanding tolerances.

Our VTL´s are equipped with angled driven tools.

Technical data:

- Max. Turning Diameter: Ø1740 mm

- Max. Turning Height: 800 mm

- Max. Workpiece Weight: 8000 kg

- Spindle Speed: Up to 250 rpm

- Spindle Motor Power: 37/45 kW

- Ram Stroke (Z-axis Travel): 900 mm

- Crossrail Travel: 750 mm

- Automatic Tool Changer (ATC): 30-tool capacity

- Control System: Fanuc

- Machine Weight: Approximately 28,000 kg

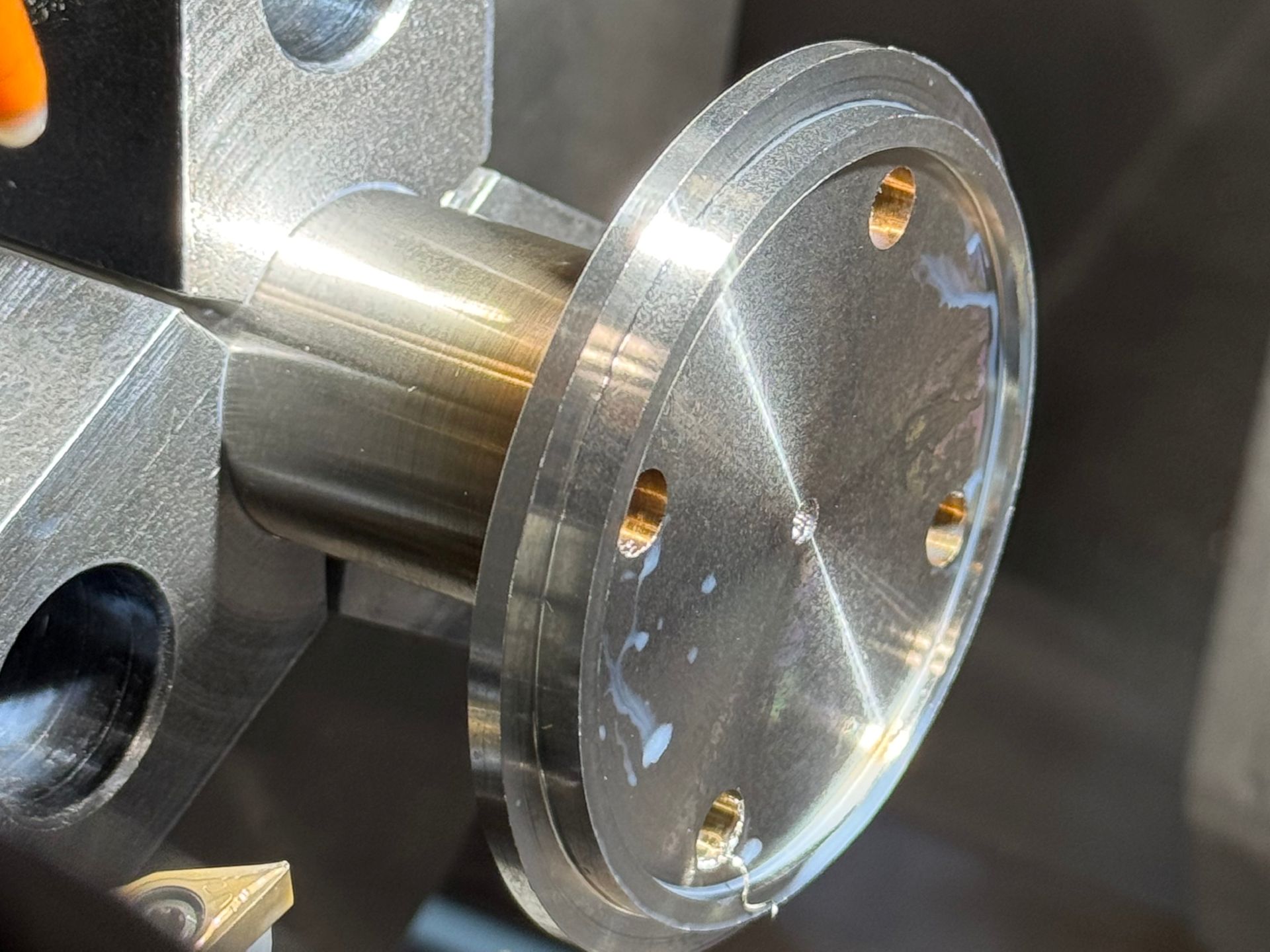

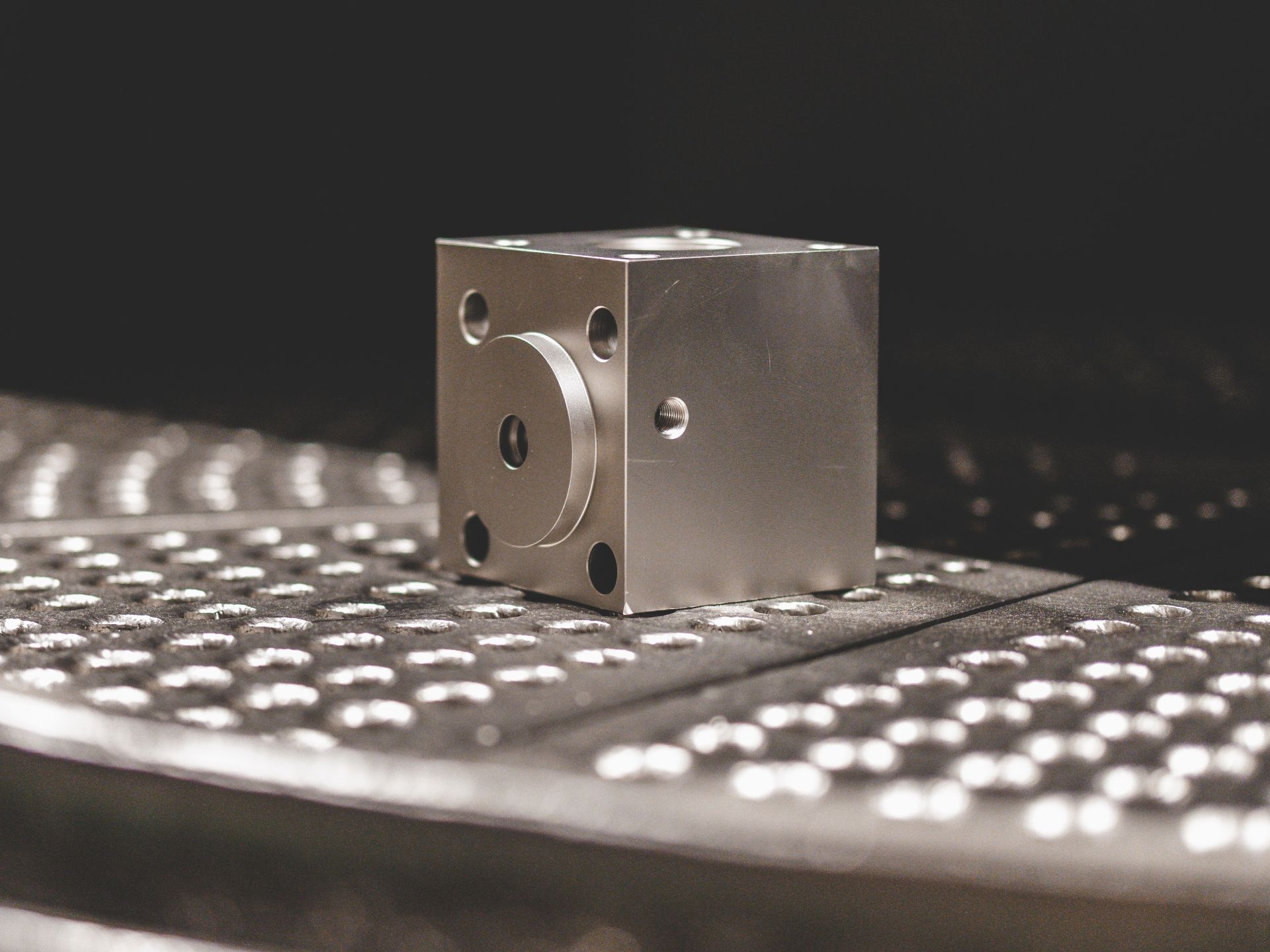

CNC Multi-Axis Mill-Turn Center

We operate seven CNC multi-axis mill-turn centers in various sizes, enabling high-precision turning and milling in a single setup. With simultaneous control over multiple axes, we efficiently machine complex geometries, reduce handling, and ensure exceptional accuracy – even for the most advanced components.

In addition, we run one 3-axis CNC milling machines, ideal for flat surfaces, pocketing, and secondary operations, giving us full control across all critical machining steps.

Technical data:

- Maximum Machining Diameter: 610 mm

- Distance Between Centers: Up to 1,500 mm

- X-Axis Travel (Upper Turret): 660 mm

- Z-Axis Travel (Upper Turret): 2,215 mm

- Y-Axis Travel: ±125 mm

- Main Spindle Speed: 35–3,500 RPM

- Main Spindle Motor Power: Up to 37 kW

- Milling Spindle Speed: 40–2,000 RPM

- Milling Spindle Motor Power: Up to 22kW

- Tool Magazine Capacity: 50–120 tools

- Tool Taper: HSK-A100

- Control System: Okuma OSP

- Machine Weight: Approximately 30,000 kg

Manual Centre Lathe - Gap Bed Design

We operate two Manual Centre Lathes, a support lathe is ideal for flexible, high-precision turning of smaller series, one-off parts, and prototypes.

These manual machines are perfect for fast setups, adjustments, and machining of custom parts.

Technical data:

- Swing over Bed: Approximately 535 m

- Swing over Cross Slide: Approximately 370 mm

- Swing in Gap: Approximately 830 mm

- Distance Between Centres: Typically 1000 mm

- Spindle Bore Diameter: Approximately 76 mm

- Spindle Nose: D1-8 Camlock

- Spindle Speeds: Variable, ranging from 20 to 2000 rpm

- Spindle Motor Power: Approximately 7.5 kW

- Tailstock Quill Diameter: Approximately 95 mm

- Tailstock Quill Travel: Approximately 180 mm

- Tailstock Taper: MT6

- Cross Slide Travel: Approximately 300 mm

- Top Slide Travel: Approximately 175 mm

- Bed Width: Approximately 400 mm

- Machine Dimensions (L × W × H): 3750 ×1700 × 2100 mm

- Machine Weight: 3500 kg